Fewer Required Batteries / Maintenance Free

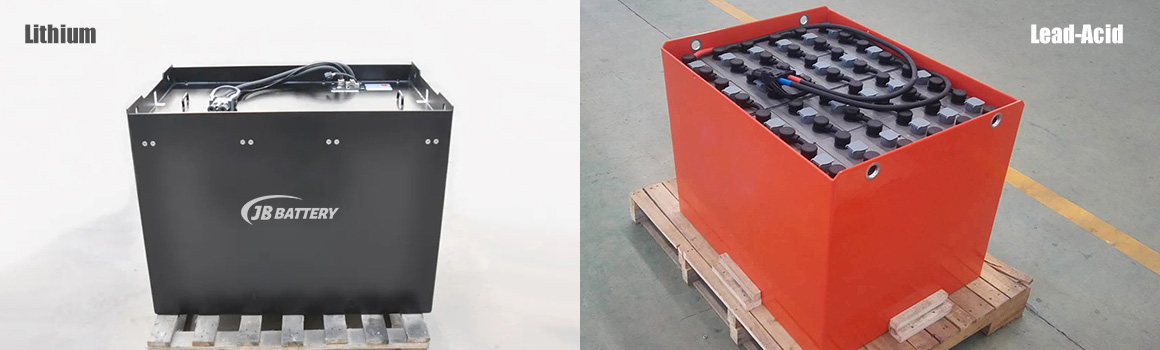

The differences between LiFePO4 battery and Lead-Acid battery

In this day and age, not all batteries function in the same way – causing many businesses to face a choice when it comes to their high-value material handling equipment and vehicles. Cost is always an issue, so making sure they are working as efficiently as possible is always key.

With so many companies in the world that rely on well-functioning forklifts to run their operations, which forklift battery they opt for can have a significant impact on their bottom line. So waht are the differences between LiFePO4 battery and Lead-Acid battery?

The World of Forklift Batteries

In the realm of forklifts, there are two preferred types of power sources businesses typically go with….lead acid or lithium.

lead acid forklift batteries are the long-standing standard, known to be reliable technology that has been successfully used in forklifts for nearly a hundred years.

Lithium-ion battery technology, on the other hand, is a bit more recent, and has significant advantages when compared to their lead acid counterparts.

Between lead acid forklift batteries and lithium-ion forklift batteries, which one is better?

There are a number of variables to consider when making the right decision for your fleet. Let’s go through a point-by-point comparison of these two distinct power sources.

Basic Differences

lead acid batteries have a case, cells with electrolyte mixture, water and sulfuric acid – they look like standard car batteries. lead acid was first invented and used way back in 1859, but this type of battery has been refined over the years. The technology involves chemical reactions with lead plates and sulfuric acid (which creates lead sulfate buildup) and requires the periodic adding of water and maintenance.

Meanwhile, lithium-ion technology was introduced in consumer markets in 1991. Lithium-ion batteries can be found in most of our portable devices, like smartphones, tablets, and cameras. They also power electric cars, like Tesla.

A big difference to many buyers is the price. lead acid forklift batteries are cheaper than lithium-ion forklift batteries up front. But the price difference reflects long-term advantages that makes lithium-ion less expensive over time.

Upkeep Of Forklift Batteries

When it comes to operating forklifts, not everyone considers the fact that their batteries require maintenance. Which type of battery you choose dictates how much time, energy and resources go toward simple upkeep.

With lead acid forklift batteries, the function of the harsh chemicals inside them mean that they need a little extra care, such as:

· Equalizing Regularly: Traditional lead acid batteries regularly experience a state where the acid and water within become stratified, meaning that acid is more concentrated near the bottom of the unit. When this happens, it can’t hold a charge as well, which is why users need to frequently achieve cell balance (or equalize). A charger with an equalization setting can handle this, and it typically needs to be done every 5-10 charges.

· Controlling Temperature: These types of batteries will have fewer overall cycles in their lifetime if they are stored in higher-than-recommended temperatures, which will result in a shorter working life.

· Checking Fluid Levels: These units must have the right amount of water to work at optimal efficiency and need to be topped off every 10 or so charging cycles.

· Properly Charging: Speaking of charging, lead acid forklift batteries need to be charged a certain way, or else they will work less efficiently (more on this below).

The list of maintenance that lead acid battery units require often lead to companies spending additional money on preventative maintenance contracts.

Lithium-ion forklift batteries, for comparison, have very little maintenance involved:

· No fluid to worry about

· Temperatures don’t affect the battery’s health until they reach extremely high environments

· Lithium-ion handles cell balancing/equalizing automatically with a battery management software system

When it comes to simplifying upkeep, lithium-ion takes an easy win.

Charging Forklift Batteries

The time it takes to charge each of these batteries is quite different, with lead acid forklift batteries taking between 8 and 16 hours to charge fully and lithium-ion forklift batteries hitting 100% in just one or two hours.

If you don’t charge either type of these batteries correctly, they can diminish in effectiveness over time. Lead acid, however, comes with much stricter guidelines and a lot more to keep track of.

For example, lead acid batteries can’t be charged in the forklift, because then the forklift would be out of commission for the 18 to 24 hours that it takes to charge and cool the battery down. So, companies typically have a battery room with shelving where they charge their lead acid batteries.

Lifting heavy battery packs in and out of forklifts creates extra handling. Battery packs can weigh hundreds to thousands of pounds, therefore special equipment is needed to get this done. And, a couple spare batteries are needed for each shift that the forklift must operate.

Once the lead acid battery is powering the forklift, it should be used only until it reaches 30% remaining charge – and there are many manufacturers that recommend not letting it fall below a 50% charge. If this advice isn’t followed, they will lose potential future cycles.

On the other hand, a lithium battery can be used until it reaches 20% of its remaining charge before any long-term damage becomes an issue. Using 100% of the charge can be done if it’s necessary.

Unlike lead acid, lithium-ion batteries can be “opportunity charged” in 1 to 2 hours while the forklift is taking a break, and you don’t even have to remove the battery to charge it. So, no fully-charged spare is needed to work a double shift.

For all matters related to charging, lithium-ion forklift batteries take much less time, are less complicated and allow for more operational productivity.

Length of Service Life

Like many business costs, purchasing forklift batteries is a recurring expense. With that in mind, let’s compare how long each of these batteries lasts (measured by their service life):

· Lead acid: 1500 cycles

· Lithium-ion: Between 2,000 and 3,000 cycles

This assumes, of course, that the battery packs are properly cared for. The obvious winner is lithium ion when talking about overall life span.

Safety

The safety of forklift operators and those managing the changing or maintenance of batteries should be a serious consideration for every company, especially with such harsh and powerful chemicals involved. Like the previous categories, the two types of forklift batteries have differences when it comes to workplace hazards:

· Lead acid: What’s inside these batteries is highly toxic for humans – lead and sulfuric acid. Because they need to be watered about once per week, there is an increased risk of spilling these dangerous substances if not done in a safe manner. They also produce noxious fumes and a high level of heat while they charge, so they should be kept in a temperature-controlled environment. Additionally, there is the possibility that they will leak an explosive gas when they hit peak charge.

· Lithium-ion: This technology uses Lithium-iron-phosphate (LFP), which is one of the most stable lithium-ion chemical combinations possible. The electrodes are carbon and LFP, so they remain stationary, and these types of batteries are completely sealed. This means that there is no risk of acid spills, corrosion, sulfation or any sort of contamination. (There is just a tiny risk, as the electrolyte is flammable and a chemical component within lithium-ion batteries creates a corrosive gas when it touches water).

Safety comes first, and so does lithium-ion in the safety category.

Overall Efficiency

The sole purpose of a battery is to generate energy, so how do these two types of forklift batteries compare in this area?

As you may have guessed, the more modern technology beats the conventional battery style.

lead acid batteries are simply always bleeding energy, as they lose amps while powering the forklift, while charging, and even while they’re just sitting there idling. Once the discharge period starts, its voltage drops at a gradually increasing rate – so they keep getting less powerful as the forklift does its job.

Lithium-ion forklift batteries keep a constant voltage level during the entire discharge cycle, which can translate into as much as a 50% savings in energy when compared to lead acid. On top of that, lithium-ion stores roughly three times more power.

The Bottom Line

Lithium-ion forklift batteries hold an advantage in every single category….easier maintenance, faster charge, higher capacity, consistent strength, longer lifespan, safer to use in the workplace, and they’re also better for the environment.

While lead acid forklift batteries are much cheaper up front, they require much more care and don’t perform as well.

For many businesses that once focused on the price difference, they are now seeing that the additional cost of lithium-ion up front is more than made up for by the many advantages that they offer in the long run. And, they are making the switch to lithium-ion!