The Different Classes of Forklift Trucks

A Breakdown of the Differences Between Types of Forklifts:

The forklift truck has been around for a century, but today it is found in every warehouse operation around the world. There are seven classes of forklifts, and each forklift operator must be certified to use each class of truck that they’ll operate. Classification depends on factors such as applications, power options, and features of the forklift.

Class I: Electric Motor Rider Trucks

These forklifts can be equipped with either cushion or pneumatic tires. The cushion-tired lift trucks are intended for indoor use on smooth floors. The pneumatic-tired models can be used in dry, outdoor applications.

These vehicles are powered by industrial batteries and use transistor motor controllers to control travel and hoist functions. They’re very versatile and are found from the loading dock to the storage facility. They’re generally used in applications where air quality needs to be considered.

Counterbalanced Rider Type, Stand Up

Counterbalanced Rider, Pneumatic or Either Type Tire, Sit Down.

Three Wheel Electric Trucks, Sit Down.

Counterbalanced Rider, Cushion Tires, Sit Down.

Class II: Electric Motor Narrow Aisle Trucks

This forklift is for companies that opt for very narrow aisle operation. This allows them to maximize the use of storage space. These vehicles have unique features that are designed to minimize the space occupied by the truck and to improve speed and efficiency.

Low Lift Pallet

Low Lift Platform

High Lift Straddle

Order Picker

Reach Type Outrigger

Side Loaders: Platforms

High Lift Pallet

Turret Trucks

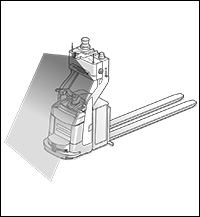

Class III: Electric Motor Hand or Hand-Rider Trucks

These are hand-controlled forklifts, meaning the operator is in front of the truck and controls the lift through a steering tiller. All controls are mounted on the top of the tiller, and the operator moves the tiller from side to side to steer the truck. These vehicles are battery-powered, and the smaller capacity units use industrial batteries.

Low Lift Platform

Low Lift Walkie Pallet

Tractors

Low Lift Walkie/Center Control

Reach Type Outrigger

High Lift Straddle

Single Face Pallet

High Lift Platform

High Lift Counterbalanced

Low Lift Walkie/Rider

Pallet and End Control

Class IV: Internal Combustion Engine Trucks—Cushion Tires

These forklifts are used inside on smooth dry floors for transporting palletized loads to and from the loading dock and the storage area. The cushion-tired forklifts are lower to the ground than forklift trucks with pneumatic tires. Because of that, these forklift trucks can be useful in low-clearance applications.

Fork, Counterbalanced (Cushion Tire)

Class V: Internal Combustion Engine Trucks—Pneumatic Tires

These trucks are most commonly seen in warehouses. They can be used either inside or outside for virtually any type of application. Because of the large capacity range of this series of lift truck, they can be found handling small single pallet loads to loaded 40-foot containers.

These lift trucks can be powered by internal combustion engines and are available for use with LPG, gasoline, diesel, and compressed natural gas fuel systems.

Fork, Counterbalanced (Pneumatic Tire)

Class VI: Electric and Internal Combustion Engine Tractors

These vehicles are versatile and can be used in a variety of applications. They can be equipped with either internal combustion engines for outdoor use or battery-powered electric motors for indoor use.

Sit-Down Rider

(Draw Bar Pull Over 999 lbs.)

Class VII: Rough Terrain Forklift Trucks

Rough terrain forklifts are fitted with large floatation tires for outdoor use on difficult surfaces. They’re often used at construction sites to transport and lift building materials to various job site locations. They’re also common with lumber yards and auto recyclers.

Vertical mast type

This is an example of a ruggedly constructed forklift and is designed to be used primarily outdoors.

Variable reach type

This is an example of a vehicle equipped with a telescoping boom, which enables it to pick and place loads at various distances and lift heights in front of the machine. The ability to reach out in front of the forklift allows the operator flexibility in the placement of a load.

Truck/trailer mounted

This is an example of a portable self-propelled rough terrain forklift that is typically transported to the job site. It is mounted on a carrier to the back of a truck/trailer and is used to unload heavy items from the truck/trailer at the job site. Note that not all truck/trailer mounted forklifts are rough terrain forklifts.

The New Class Smart Material Handling Machine

Automated Guided Vehicles (AGV) :

Rough terrain forklifts are fitted with large floatation tires for outdoor use on difficult surfaces. They’re often used at construction sites to transport and lift building materials to various job site locations. They’re also common with lumber yards and auto recyclers.

What is an AGV?

AGV stands for Automated Guided Vehicle. They are autonomous driverless vehicles that follow a planned route using various types of guiding technology such as:

· magnetic strips

· marked lines

· tracks

· lasers

· a camera (visual guiding)

· GPS

An AGV is powered by a battery and equipped with safety protection as well as various auxiliary mechanisms (such as load removal and mounting).

Its main purpose is to transport materials (products, pallets, boxes, etc.). It can also lift and pile loads over a long distance.

AGVs are often used inside (factories, warehouses) but can also be used outside. Amazon is known for using entire fleets of AGVs in its warehouses.

AGV and AGV system

An AGV system is a complete logistics solution that brings together all the technology that allows the AGV to move properly. It includes:

· Solution elements: load handling, load transport, feed order and safety;

· Technological elements: traffic control, navigation, communication, control of load handling devices and safety system.

What should JB BATTERY do for this forklifts?

As the class name of the forklift, you can see large of them are using electric power driving. JB BATTERY dedicates to research the best batteries for the electric power forklift. And we offer the LiFePO4 batteries with energy efficiency, productivity, safety, adaptability, and high performance.