Fewer Required Batteries / Maintenance Free

Advantage of JB BATTERY

High Energy Density

The LiFePo4 battery packs found in our forklifts have double the energy density of a lead-acid battery that has the same dimensions. The voltage supply is also stable throughout the energy discharge. Both of these lead to longer run times for the end-user.

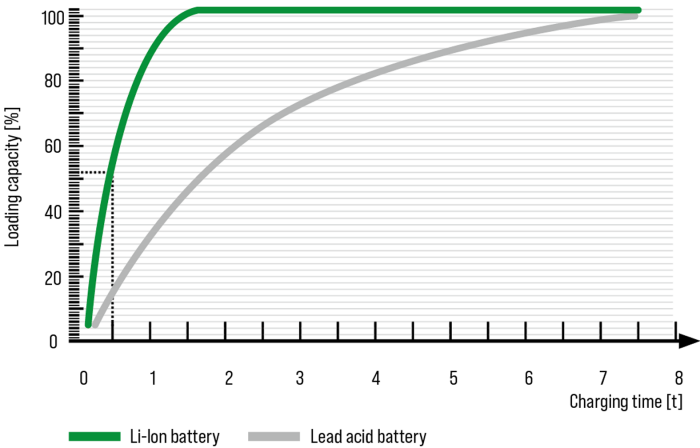

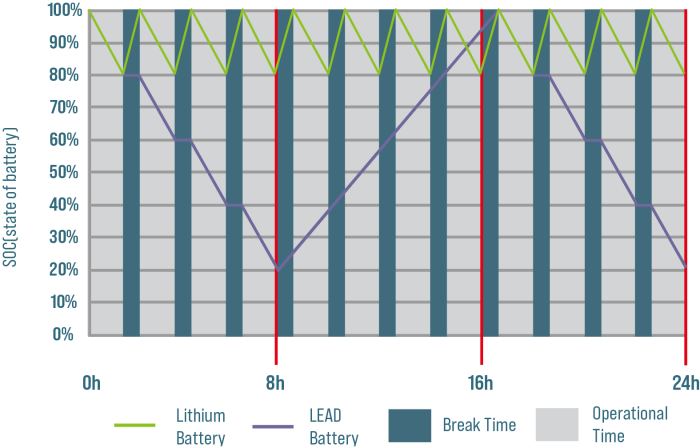

JB BATTERY’s LiFePO4 batteries supply the forklifts take 2 hours to fully charge compared to charging a lead-acid battery truck for 8-10 hours and allowing it to cool down for another 8-10 hours. The LiFePO4 technology also allows for the trucks to run in three-shift environments thanks to opportunity charging. This allows the end-user to continuously run the forklifts for three shifts if they charge the battery during their breaks. The only way a lead-acid truck is able to run three shifts is by having three batteries and switching them out between shifts.

Efficiency

Charging Times Comparision Chart

Opportunity Charging Comparision Chart

Maintainance Free

LiFePO4 battery packs do not require the manual maintenance that lead-acid battery packs do. For example, lithium-ion batteries do not need to be watered or have acid level checks performed. Because of this, our lithium-ion battery packs are virtually maintenance-free.

The battery management system that JB BATTERY uses with the LiFePO4 battery packs is designed to continually monitor the LiFePO4 cells and other vital components. It offers overcharge/over-discharge protection, fault monitoring, battery health estimates, battery current/voltage detection, and a low cost/low power consumption feature. These features are all put in place to make the LiFePO4 battery packs, found in the forklifts, the most reliable power option offered.

Battery Management System

Warranty/Long Life Cycle

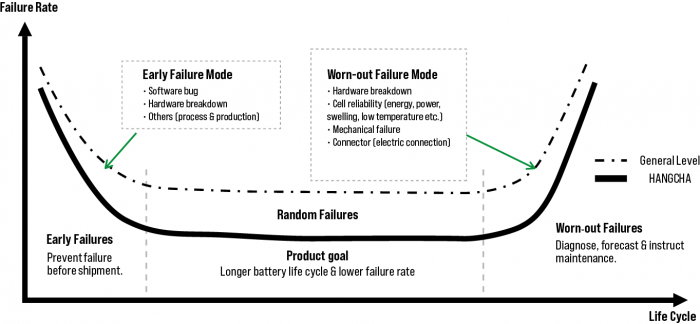

The lithium-ion battery packs found in JB BATTERY’s material handling equipment are designed to last a long time. Because of this, JB BATTERY offers up to a 10 year or 20,000 hour warranty on our Lithium Iron Phosphate (LiPO4) battery packs. The battery packs will retain at least 80% residual capacity over 4,000 full charges. As seen in the Bathtub curve below, the lithium-ion batteries designed by JB BATTERY are considerably less prone to failures when compared to the average amount of failures a lithium-ion battery has over its life cycle.

Opportunity Charging Comparision Chart

Thanks to an electrical heating element, the LiFePO4 material handling equipment can run in cold applications. When compared to a lead-acid powered truck, the batteries in the lithium-ion heat up to 32 degrees F in one-third of the time it would take the lead-acid powered truck. This allows the LiFePO4 powered material handling equipment to maintain a high level of performance at temperatures below freezing.

Cold Area Application

Beneficial to the Environment

LiFePO4 batteries do not release harmful emissions into the environment, use acid, and have twice the service life when compared to lead-acid powered forklifts. They are also substantially more efficient when charging and discharging and are completely recyclable. Because of this, LiFePO4 batteries are extremely beneficial to the environment.

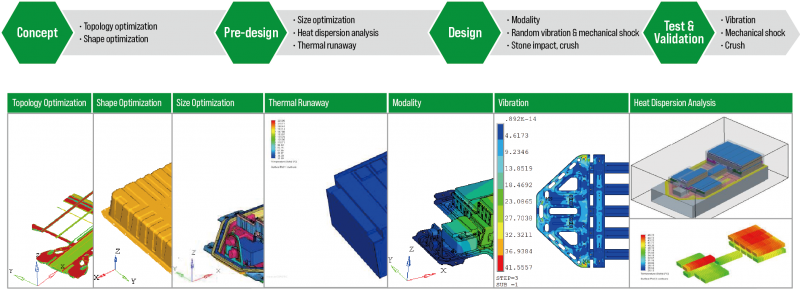

LiFePO4 Battery Safety

LiFePO4 battery is extremely safe, thanks to JB BATTERY’s design, battery chemistry, and testing. The battery packs are designed to not release any harmful gases, work without the use of acid, and prevent operator strain by not needing to change the battery packs as the operator would with traditional lead-acid forklifts. Thanks to the intelligent battery management system, the battery is constantly monitored to make sure the forklift is safe to operate.

Lithium Iron Phosphate Chemistry

The battery packs were designed to use Lithium Iron Phosphate (LiFePO4) chemistry. This chemistry has been proven to be both the safest and most energy-efficient chemistry currently found in lithium-ion technology. The chemistry is also stable and won’t react with the environment if the casing were to be punctured. Lithium Iron Phosphate chemistry ensures a safer operating environment.

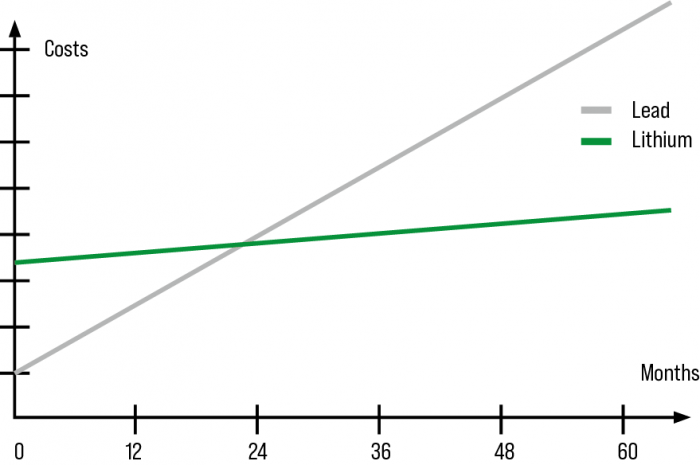

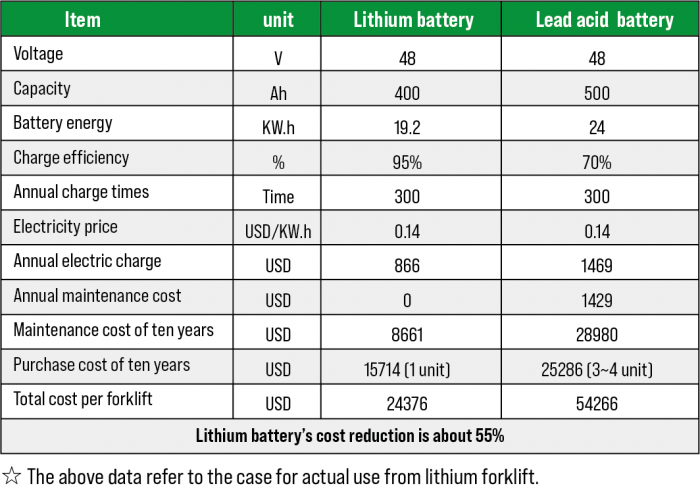

Total Cost of Ownership (TCO)

Although entry cost is high, the LiFePO4 product line from JB BATTERY makes up for it with a cost reduction of about 55% when compared to a lead-acid battery. This means that the total cost of ownership is significantly less than it would be with a lead-acid forklift. It is less thanks to the LiFePO4 forklifts lower operating costs, efficiency, and longer times between service.

Total Cost of Ownership Comparision Charts